Types of hatcheries

Many types of hatcheries have been established so far for hatching fish eggs. The main aim of the hatcheries is to improve the percentage of the hatching of eggs. The different types of hatcheries are :

Earthen hatching pits

The earliest hatchery was the earthen hatching pit with a dimension of 3′ x 2′ x 1′. Based on the requirements the size may vary. These pits are prepared in several rows and their inner walls are plastered with mud. After filling them with water, the collected eggs are introduced into them. About 35,000-40,000 eggs per pit are kept for hatching. Hatching takes place within 24 hours. Pits are also interconnected, properly irrigated and have draining facilities. A constant flow of water is useful to ensure proper aeration and to reduce the accumulation of wastes, thereby improving the survival rate. The percentage of hatching in hatching pits is 30-40%.

The advantages of earthen hatching pits are :

1. These are best suited for hatching eggs from dry bunds. Wide areas near dry bunds can be used for digging earthen pits, so as to use a less quantity of eggs in each pit.

2. Fresh accumulated rain water from the bunds enters into the pits for hatching.

3. Expenditure is very low and the technology is inexpensive.

These pits have some disadvantages also. Huge mortality often occurs due to fluctuations in temperature, because the eggs are hatched in open areas. Depletion of oxygen often occurs which causes heavy mortality of spawn. Continuous water flow has to be maintained in the pits till the spawn are collected. If sufficient water is not available, mortality of spawn occurs.

The Chittagong type of hatching pits are similar to earthen hatching pits, but in each pit a piece of cloth and mosquito nets are used additionally. The cloth is kept just above the bottom of the pits. The mosquito net is arranged above the cloth. The spawn, after the hatching, pass through the net and are collected on the cloth. The net containing the egg shells and the dead eggs is removed after 3 days of hatching. When the yolk sac is fully absorbed, the spawn are taken out

Earthen pot hatcheries

This is the oldest method adopted for hatching. Locally made earthen pots are used for hatching. The collected eggs are kept in pots and hatching takes place inside the pot. The fluctuations of temperature and pH are moderate. This method is not very popular. The percentage of hatching is about 40%.

Cement hatching pits

The hatching pits are lined with cement. The eggs are kept in these pits for hatching. The main advantages of these pits are that the recurring expenses are less, they are easy to operate, and regular flow of water is maintained. But capital investment is high and the mortality is mainly due to depletion of oxygen and increase in water temperature. The percentage of hatching is 30-50%.

Hatching hapas

Double cloth hatching hapas are most extensively used. The hapa is fixed in the water with the help of bamboo poles in shallow waters. This hapa is double walled, with an outer wall made of either thin or coarse muslin cloth, and an inner wall made of round mesh mosquito netting cloth. The most frequently used cloth for a hatching hapa is 2 x 1 x 1 m in size for the outer one, and the inner wall size is 1.75 x 0.75 x 0.9 m. The water depth is maintained around 30 cm. These hapas are arranged in a series. 75.000-1,00,000 eggs are kept in one hapa inside the inner wall for hatching. After hatching, the hatchlings enter into outer hapa through the mosquito netting cloth, leaving the egg shells, the spoiled eggs and the dead eggs. After hatching, the inner hapa is removed. The hatchlings in the outer hapa are kept for a period of 40 hours till the yolk sac is absorbed. The percentage of hatching is 40-50%.

The main advantages are that the cost is very less and the eggs are away from earth which will not pollute and cause mortality. The disadvantages are the pores of hapas get clogged due to silt deposition which causes heavy mortality, crabs cut the hapas easily, they have a short life period of about 2 years, weather fluctuations result in mortality and they need more water.

Garfil hatching hapas can also be used in place of cloth hapas. The design, construction and arrangement are similar to cloth hapas. The hatching percentage is 50-60%. The advantages are suitable mesh size can be selectively used for inner and

Floating hapas

Floating hapas are an improvement over the conventional hapas. These are designed to cope with the rise and fall in the water level. These can be easily fixed even in rock}’ areas without bamboo poles. They can also be fixed in deeper areas so that a mild water current passes through the hapa: this helps in better exchange of water and aeration. It is similar to a conventional hapa, but it is mounted on frames which are made up of polythene or aluminum pipes. Floats are fixed to the hapa for floating. It is tied to fixed objects with long ropes so that it will not be carried away by the current. It is collapsible and can be assembled very easily. The size of outer hapa is 2 x 1 x 1 m and that of the inner one is 1.75 x 0.75 x 0.5 m. The hatching percentage is 50-70%. Silt may get deposited in the hapa which causes mortality of the spawn. It may be dispositioned due to the movement of water and rearranging is time consuming. The hatching rate is not high.

Tub hatchery

This hatchery was introduced in Madhya Pradesh. It is an improvement over fixed hapas and provides for hatching in running water. It has a continuous flow of water by gravity and siphons. This system has a series of 8-12 glavanised iron hatching tubs connected to each other with a regular flow of water. Each series consists of an overhead drum. Each tub is 2.5′ x 2.5′ x 1.5′ in dimension and has two nets, an outer and inner one. The fertilised eggs are transferred into the tubs for hatching. The percentage of hatching is 50-70%. Vigilance round the clock is necessary in this system.

Cemented cisternae hatchery

Tub hatchery has been replaced by cement cisternae hatchery. Cement cisternae are built below the dams of the dry bundh. Pond water is supplied to these cisternae. Each cistern is 2.4 x 1.6 x 0.45 m in dimension and they are connected in two rows. These are not interconnected and each has separate inlets and outlets. About 3,00,000 eggs are kept in each cistern for hatching. The percentage of hatching is 50-70%.

Vertical jar hatchery

This technique is an improved method over the hapa technique and ensures 90% survival offish hatchlings. The hatchery (Fig. 5.7) consists of a continuous water supply, breeding tank, incubation and hatchery apparatus and a spawnery. The vertical jars are made up of glass, polythene and iron.

1. The greatest advantage of the jar hatchery is its very low water requirement. One unit of 40 jars can handle 20 lakh fertilized eggs in a day, and it would need just 20,000 litres of water.

2. It can be operated in a compact area. The space needed to accommodate the 40 jars unit would be around 10 square metres or at the most 20 sq. metres, and such a unit is sufficient for hatching out 20 lakh eggs. Compared to this, the hatching hapa in ponds requires 150 square meters of space.

3. In summer, with the water temperature shooting up over 320 C, hatching will be adversely affected in hapas. But in jar hatcheries, it is possible to overcome this by air-conditioning the room.

4. Developing embryos can be seen with naked eyes and so rectification can be attempted depending on exigencies.

5. A set of 40 jars would cost Rs. 10,000 with accessories. These jars last for 10 years. Hence, the cost per year for 20 lakh hatchlings would be Rs. 1000. But in the case of hapas, to handle 20 lakh hatchlings costs Rs. 9000. The hapas last only for two years and involve more labour. This indicates that jar hatchery is more convenient and also more economical cost-wise.

6. In a day, in a space of about 20 square metres, one can hatch out 20 lakh eggs with a survival rate of about 90%. During the monsoon period about 200 million eggs can be handled in this hatchery.

7. An added advantage of the jar hatchery is that in the same air-conditioned room even breeding can be carried out successfully. Breeders respond well at temperatures of 26-28° C.

8. Adverse water conditions can be changed in ajar hatchery. In summer the hydrogen sulphide content is increased, especially in reservoirs, and this affects the hatching in hapas in the ponds fed with the above water. This could be treated in overhead tanks before supply to the hatchery jars.

The main disadvantages are as it is made of glass, it is prone to easy damage; difficult to shift to different places and subject to breakage during transport; temperature control system is not provided; metabolites are not removed from the circulating water, and. additional air circulation is not provided.

In the transparent polythene sheet hatchery, glass jars are replaced by transparent polythene containers. Each polythene jar is 27 cm in height, 10 cm diameter and has a capacity of 2 litres. In the giron jar hatchery, glass jars are replaced by galvanised jars. This unit is durable, cheaper and has more capacity. It is also more suited for local village conditions. The jars are conical and have a short spout at the top to serve as an outlet. The height of the jar is 75 cm and its diameter is 23 cm. The jars are fixed in an angular iron framework. The rate of the water flow is maintained at about 1 lit/min.

Plastic bin hatchery

This unit consists of eight hatchery cum spawnery units (HCS units) and a 5,000 litres water tank. The tank receives water from a natural resource by pumping. The tank is connected to the inlet pipelines of each unit. The HCS units can be arranged in a series to facilitate inlet connections. In this hatchery 2 crore eggs are kept for hatching. The percentage of hatching is 70-80%.

Each unit consists of an outer container and the inner common egg vessel. The outer hatchery container is a rectangular aluminium sheet tub of 54″ x 18″ x 22″ dimension and 243 litres capacity. It is unequally divided into three chambers. At a time 8 litres of eggs are placed for hatching in each hatchery unit. It also consists of an inlet outlet and drain pipe.

The common egg vessel is made of a 14 gauge aluminium sheet which has 2.5mm diameter perforations. Three egg vessels are placed in each outer container. It is cylindrical in shape with a 12″ diameter and 12″ height. There is an arrangement of a plunger-lid which can slide and can be fixed at any desirable height on a vertical aluminium rod having a series of holes at 1 cm distance. The lid is useful to cover the eggs placed in the vessel closely so as to prevent any over flow and at the same time to enable efficient circulation of water. Each egg vessel can hold about 2 lakhs of eggs.

The advantages are that the cost is less as it is primarily made of plastic, and is easy to operate. The disadvantages are that it has no temperature control device, no additional air circulation, metabolites may not be removed from circulating water and rhegaplankton may come from the overhead tank, which are injurious to the spawn.

Plastic bucket hatchery

It consists of an outer plastic bucket with a perforated aluminium bin egg vessel and a galvanised iron sheet spawnery. The plastic bucket height is 47 cm, 30 cm diameter and the capacity is 45 litres. It has 3 inlets at the bottom and 2 outlets at the top. The eggs are kept in the egg vessel for hatching. The survival rate is 70-80%.

Hanging dipnet hatchery

This hatchery unit has a spawning tank, two hatching tanks, two breeding tanks and an overhead tank. The spawning tank is 2.36 x 3.23 x 0.9 m, hatching tanks are 3.3 x 1 x 1 m and breeding tanks are 1.2 x 0.7 x 1.06 m in size. The water is supplied from an overhead tank, which is fixed at 3.2 m height over the roof. All the tanks are with inlet and outlet pipes. Sprayers are fixed over all the tanks. Air coolers are used for cooling the water. Hatching dipnets are fixed in the hatching tanks. These nets are barrel shaped with steel rings. The size of the net at the top is 65 cm and at the bottom 46 cm. Dipnets are covered with 1/16 inch mesh cloth. A 50 mm brass spray head is fined at the bottom of each net. About 1 lakh eggs are kept in each net. During hatching, 1-1.5 lit/min water flow is maintained. The hatchlings enter into spawning tanks. The percentage of hatching is about 80%.

Circular cisternae hatchery

It has a drum which is made up of a galvanised iron sheet with one metre diameter and one metre height. At 5 cm above the bottom of the drum an inlet pipe is fixed at an angle of 45°. The inlet pipe is connected with the main water supply. Near the inlet a check valve is fixed to regulate the incoming water flow into the drum. The inlet pipe creates water circulation inside the drum. The surplus water goes out through the outlet, which is fixed at the top of the drum. The eggs are kept in the drum, and due to the water circulation the eggs are also circulated. A monofilament cloth with 60 mesh per inch at the outlet prevents the escape of eggs. After the hatching the egg shells get disintegrated and escape along with the surplus water. The hatchlings are found inside the drum and these are collected later. Due to the circulation of water plenty of dissolved oxygen is available to eggs and hatchlings. The percentage of hatching is about 90%.

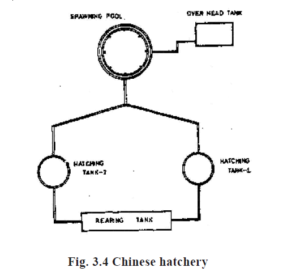

Chinese hatchery

The Chinese spawning and hatching systems are based on continuous flow of water by gravity to breed carps and hatch the eggs. The cost of construction and operation of a Chinese hatchery is less when compared to any other design for die same production capacity. In India also, the Chinese hatchery system is now considered to be highly suitable for the production of quality fish seed. Chinese type of. hatchery (Fig. 3.4) consists of four main components, viz., overhead water storage tank, the spawning/ breeding pond, incubation hatching pond and hatchling receiving pond. This system is designed for fish breeding and incubation. The water required for the hatchery system is regulated thf oogh the pipe supply from an overhead tank. The duration of one operation for hatching is 4 days. It can be repeated after a period of 4 days.

Overhead water storage tank : The floor of the tank should b 2.6m. above ground level. The inside dimension should be 5.5 x 2.7 x 2.2m and it should have a 30,000 liters capacity. Water supply to the overhead tank should be arranged by pumping water from an open well or a deep tube-well. The overhead tank is used to supply sufficient water for the spawning, incubation and storage tanks. A smaller overhead tank with a 5,000 litres capacity is also useful for this type of an operation.

Spawning pond : It is a circular masonary/concrete pond with an inside diameter of 8 m. It has 50 cubic metres of water holding capacity. The inside depth at the periphery is 1.20 m. which slopes down to the centre at 1.50m. A water supply line is laid along the outside of the wall, and the inlet to the pond is provided at 14-16 places equally spaced and fixed at an angle of 45° to the radius of the tank using a 20 mm. diameter pipe with a nozzle mouth, all arranged in one direction. These are fixed to the vertical wall and the nozzle mouth is flush with cement plaster face and near the bottom along the periphery of the pond. In the fitted through which, on opening the valve, fertilized eggs along with water are transferred into incubation pond for hatching. The \vater flow in the spawning pool create an artificial riverine condition for the fish to breed. The shower and a perforated galvanised iron pipe are useful to increase the dissolved oxygen. About 70 kg. of males and 70 kg. of females can be kept in the spanning tank which can yield 10 millions of eggs in one breeding operation.

Incubation ponds: There are two circular incubation ponds each of 3.6 m. internal diameter. There are 2 chambers in each pond. The dimension of the outer chamber is 4 m.. having an outer masonry/ concrete wall. Another circular wall with a fixed nylon screen is provided at 0.76 m. clear distance from the outer wall. These tanks are about one metre in depth with 9-12 cubic metres of water holding capacity.They hold 70,000 million eggs/cubic metre. The inner chamber is provided with 10 cm. diameter vertical outlets with holes at different heights for taking out excess of \\ater of the incubation pond. The spawn along with water flows from these ponds to spawn collection pond.

From the overhead tank., the initial 7.5 cm. diameter pipe line is reduced to a 5 cm. diameter pipe line, and then to a 1.2 cm. diameter pipe line. 8 number of outlets are fitted in the floor of the incubation pond, with each outlet having duck mouth opening fixed at an angle of 45° towards inner wall. All the outlets are fixed in one direction only. Water supply pipes are fitted from the circular spawning tank by a 10 cm. pipe line which is then bifurcated into 2 pipelines off cm. diameter each, one for each of the incubation tanks which are further connected to duck mouth outlets in the floor of incubation ponds. There is an outlet of 7.5 cm. diameter through which the hatchlings pass into the hatchling receiving pond. This opening is also used for complete dewatering of the outer chamber of the incubation pool. Desired water movement is about 0.2-0.3 m/sec.

Hatchling receiving pond: This is a rectangular masonry concrete tank. The inside dimensions are 4 x 2.5 x 1.2 m. This is located at a lower elevation than the incubation pond. So as to drain out the water from it by gravity, lift ground levels may permit. Fresh water supply from the overhead tank is provided by a 7.5 cm. diameter pipe line, bifurcated into 3 numbers of 3cm. diameter pipelines. These pipelines are arranged so as to provide the spray for aeration. From each of the incubation ponds 7.5 cm. diameter pipes are provided for transfering and regulating spawn intake into the spawn receiving pond. Hooks are fixed in two opposite side walls of the pond for fixing the net for the collection of spawn. Steps are also provided for getting into the pond for the collection of spawn. The overflow from this pond is discharged into an open drain and suitably utilised in the earthen ponds, if possible.

Operation of the Chinese hatchery: Brooders are kept in the spawning pond for about 4-8 hours for conditioning. Then between 4-6 PM, the first injection is given to the females. After 6 hours a second dose of injection is given to the female and one dose to the male. After 4 hours of the injection, the water jets are started so as to get the circular motion in the water. After 4-8 hours of the second injection, breeding takes place. One crore of eggs can be treated at a time in one operation. The eggs are collected from the bottom and are transferred into the incubation pools through pipes by opening the valves.

Arrangements are made to chum the water again in the incubation pools. In 4 days time, the spawn is about 6 mm in size and then it is taken into the hatching’ spawn receiving pool. From there it is lifted and stocked in separate water ponds until they reach the fry stage. If oxygen is less, aeration can be given through a compressor in the incubation pool at the rate of 6 kg/ cm2 run by a 1 HP motor. For aeration-water showers, water jets, etc can also be provided depending upon the requirement. During the breeding season lasting about 120 days in a year, the breeding and hatching operations can be carried out in about 30 batches, each batch of 4 days. About one crore eggs can be hatched in one batch, and with a 95% hatching success, 285 million spawn of about 6 mm size can be produced. The main advantages are that the structures are of permanent nature, the hatchery is easy to operate and it needs less manpower.

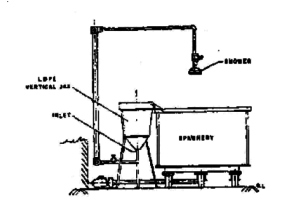

D-variety Hatcheries

The seed production is dependent on nature, but the problem has now been solved with the evolving of a modern hatchery model CIFE-D-81. It is now possible to breed fish without rains in this modern hatchery. Thus, we have become independent of the monsoons and natural environment. The brooders are kept in the breeding unit, while hatching is done in jars having control over silt, oxygen, temperature and metabolites. This hatchery system (Fig. 3.5.) consists of breeding and hatchery units.

Breeding Unit: This unit consists of air conditioners, breeding tanks, sprayers, water current system, aeration system, water pumps, overhead tanks and a filter unit. The breeding unit is installed in an air-conditioned room. An air conditioner of 1.5 ton capacity is used. The air-conditioned room may have an area of 22.5 sq.m. and two breeding tanks of 440 x 115 x 80 cm size each, for breeding 240 kg females in 30 operations in four months of breeding season. The breeding tanks are either plastic pools, LDPE tanks, cement tanks or fibreglass tanks. The breeding tanks are provided with fine 75 mm diameter showers and spray channels arranged around the upper edge of the tanks. The spray and showers have independent operating systems, but can be used

simultaneously if required. The water in the breeding tank is recirculated by a 1/16 HP pump and oxygenated through spray and showers. In each of the breeding tanks two floating hapas 180 x 90 x 90 cm in size are arranged. In each floating hapa a close net hapa of 170 x 80 x 80 cm size with a mesh of 20 mm and an opening for the introduction of injected brooders is fixed. In this system, 2.4 million eggs can be obtained in one operation.

Reservoir, pond or tube well water is directly pumped through the filter unit to remove silt and suspended solids into overhead tanks. Water is supplied to the breeding tanks through spray and showers from overhead tanks. The spray and showers increase the dissolved oxygen, keep the water cool and simulates natural conditions. Besides, aeration is also arranged by means of an oil free air compressor or blower.

Hatching unit: This unit consists of overhead tanks, vertical hatchery jars, oil free air compressor and blower, spawneries, spray and floating hapas. The hatchery is installed in a shed or building, where temperature can be maintained at 27-29° C. Aeration is arranged to increase the dissolved oxygen of water between 7-9 ppm. The hatchery jars are made up of low density polythene. The height of the jar is 62.5 cm, the upper part is 44 cm and the capacity is 40 litres. A 37 cm diameter pipe with a control valve is fitted below the jar. Each jar has an independent control valve. The outlet is found at the top of the jar. The jars are arranged in a series. An inner egg vessel of 20 litres capacity is used inside the hatchery jars for removing the egg shells after hatching. Every three jars are provided with a spawn receiving low density polyethylene tank of 1450 litres capacity, 6′ diameter and 3′ height. Water spray is arranged around the upper edge of each tank.

Spawn receiving tanks: The spawn receiving tanks are provided with 50 mm diameter overflow pipes, which are connected to the storage tank, from which the water is again pumped back to the overhead tank through a filter for recirculation. A fine meshed nylon floating hapa is arranged in the spawn receiving tank to accommodate the spawn. The spawn is received from the hatchery jars to this hapa through a 32 mm diameter flexible PVC pipe to avoid any injury to the spawn. Showers and spray are provided to cool and aerate the water. Aeration is arranged in the hatchery jars and also in the spawn receiving hapa to increase the dissolved oxygen level, and the eggs are kept in floating condition in the egg vessel.

Operation of D-81 hatchery unit: Selected breeders are subjected to induced breeding and introduced in the breeding hapas. In case the water temperature is too high, the fishes are acclimatized gradually by lowering the temperature to 26-27° in the breeding unit. Then the spray and showers are started. The air-conditioner is put off when temperature reaches 26° C, but the spray and showers are kept in operation.After breeding takes place, the big meshed hapa is removed along with the spent brooders. The eggs remain in the breeding compartment of the hapa. After 5 hours the eggs are transferred to the hatching unit.

After 4 hours of spawning the eggs are transferred to the egg vessel which is fixed in the hatchery jar. About 2 to 2.25 lakh eggs can be accommodated in each hatchery jar depending on the species. Continuous mild aeration and water flow are maintained in the jars for free floating of eggs. The rate of water flow is maintained at 1-2 litres/min. The eggs hatch within 14 hours. When the hatching is complete, the egg container with the shells is removed. Then the flow rate of water in the jars is slightly increased for speedy transfer of the hatchlings into the spawn receiving tank. The remaining hatchlings if any are transferred into the hapa by siphoning with a 25 mm diameter pipe. Once the jar is emptied, water flow in the hatchery jars is stopped. The spray is arranged around the upper edge of the spawn receiving tank and is kept in operation to ensure high level of dissolved oxygen and low temperature. The aeration and spray are kept in operation continuously until the yolk sacs of the hatchlings are absorbed, which normally takes 2 days. The percentage of hatching is 93-98%.

The advantages are :

1. Material used is low density polyethylene, hence difficult to break.

2. Easy to pack and transport to different interior places.

3. Controlled temperature system is introduced.

4. Metabolites are removed from the circulating water by filtration.

5. Due to the additional aeration, oxygen in water is raised to 7-9 ppm.

6. Even when fertilization of eggs is low, the hatching rate is high.

7. The system ensures breeding and hatching without rains and monsoon.

8. Due to the filtration, the water is free from sediments and silt.

9. Each jar has a provision for independent regulation of aeration and water flow. In case of mortality, pollution or disease in any of the jars, it can be isolated from the rest of the system.

10.The common carp eggs normally hatch in 72 hours, but in this system these hatch out within 42 hours.

This system has no disadvantages at all. During 1984, large size HDPE D-84 jars were used in place of polythene jars. HDPE D-84 jars of 160 litres water capacity and a loading capacity of 0.75 million have been designed and successfully operated with a 92-95% survival rate.

Source: Aquaculture