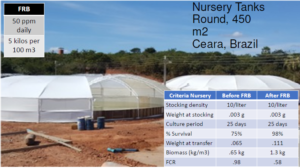

• Before FRB: 60-75% survival

• After FRB: 80-90% survival

• Juveniles grew faster (2-5 days)

• Increased survival in grow-out ponds

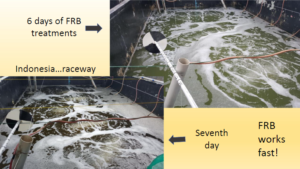

• 50 ppm FRB daily (5 kilos per RW)

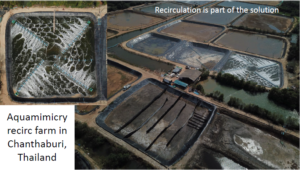

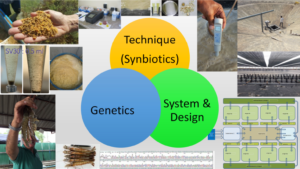

Synbiotics and recirculation for extensive grow-out systems

Survival using FRB only: 40-60%

Survival using FRB + recirculation: 60-80%

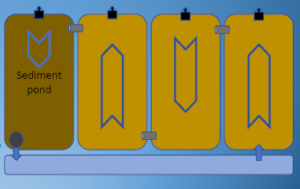

Recirculation model: Within grow-out ponds

Harvest: 2,500-5,000 kilos per hectare

Survival: 75-85%; 150 days; 30-33 grams

• Series of 2-5 ponds

• Up to 7 hectare ponds

• Ecuador and Mexico

• Zero aeration; static ponds

• Daily exchange: 1% (before 10%)

• One pump; gravity flow

• Stocking density: 20-30/m2

Water movement helps to optimize synbiotics in extensive ponds

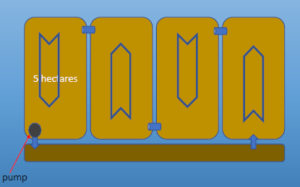

Recirculation in parallel

• Farm level or groups of ponds

• Staggered stocking

• Longer period to balance water quality

• Large pump and energy costs

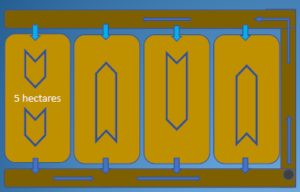

Recirculation in series

• 2-6 ponds

• Batch stocking

• 2 grams – recycle

• Free board: 5 cm

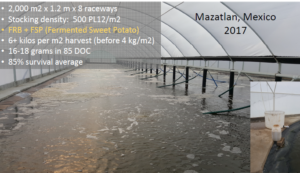

Shrimp Farm in Mexico

Before: Open exchange of 10% pond volume per day for entire farm; 80% mortality due to EMS

Plan for 2018:

• synbiotics and recirculation

• 1% open exchange per day

• 12 hours of recirculation per day (night)

FRB without aeration

• Mix FRB 2-3 times per day

• 24 hours of anaerobic fermentation

• 15 kilos of rice bran / hectare / week

• Applied every 2-3 days

• Mineralize pond bottom w/enzymes & FRB

• Before and after stocking

• Breaks up biofilm, enhances diatoms

• 1-2 times per week (rope for lined ponds)

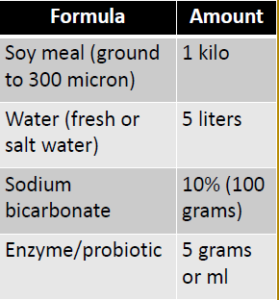

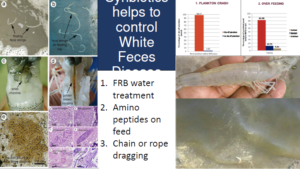

Amino Peptide (AP) Emulsion

• Protein (from soy) converts to amino acids and peptides

• 5 to 7 day anaerobic fermentation (stir daily)

• 10-20% AP emulsion on one feeding per day

Application

Top coat for feed – 100-200 ml per kilo

Fermentation period of feed – 1 to 12 hours before feeding

Feed treatments – One feeding per day

Direct pond treatment – 2 ppm/hectare; twice weekly

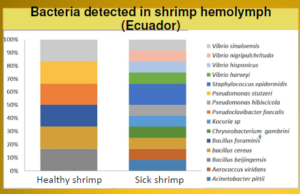

Bacteria detected in shrimp hemolymph (Ecuador)

Amino Peptide(AP) Emulsion Protocol

• Top coat for feed: 100-200 ml per kilo of feed

• Treat one feeding per day

• Direct pond treatment: 2 ppm per hectare twice per week

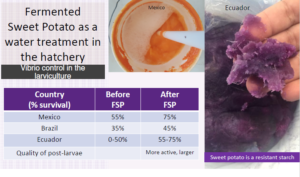

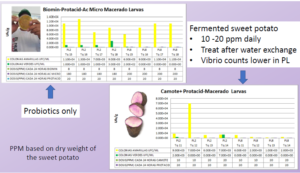

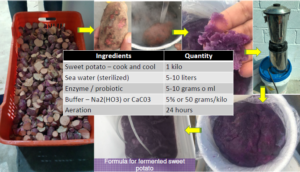

Fermented Sweet Potato as a water treatment in the hatchery

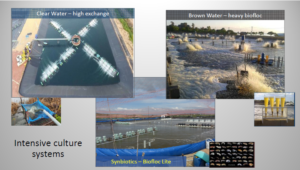

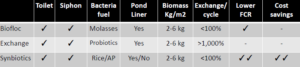

Comparing biofloc, high exchange and synbiotics

1.Biofloc – difficult to manage organic load

2.High exchange – water storage, high energy, discharge, higher FCR

3.Synbiotics – low organic load, water exchange, FCR, easy to manage

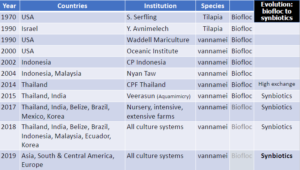

Synbiotics is a long-term and sustainable solution Back to the future…

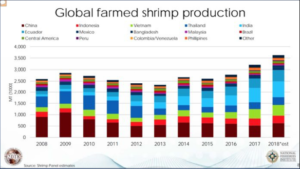

Source: Society of Aquaculture Professionals (SAP)